23.10.2023

Dental

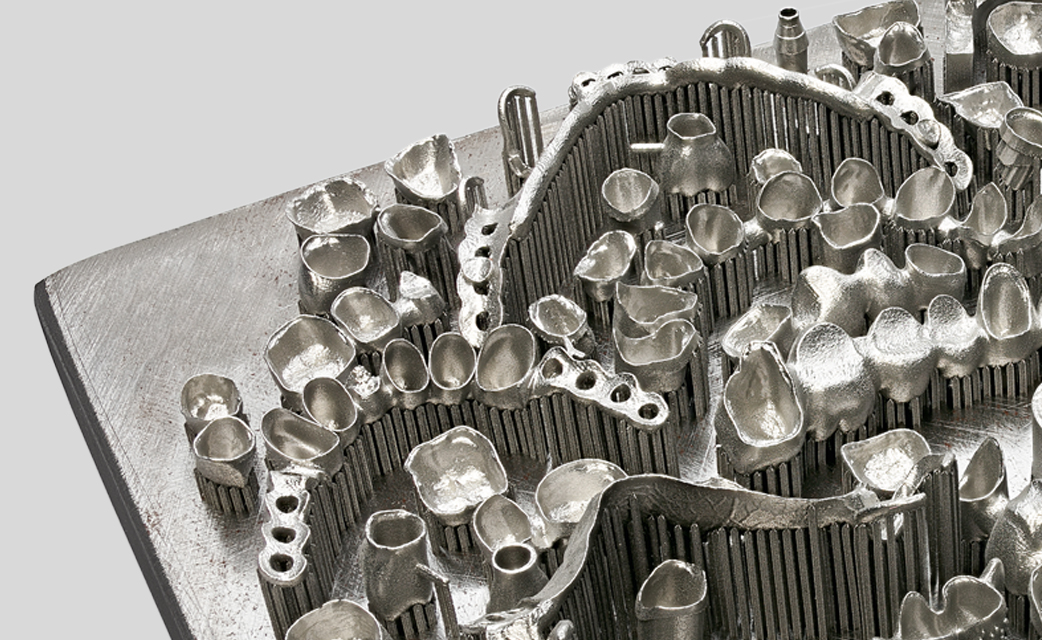

Dentures from the 3D printer: the future of dentistry

The field of dentistry has been undergoing fundamental change for more than 15 years now. The background to this is the developments in the field of 3D printing. This technology makes it possible to produce dental prostheses using 3D printers – a breakthrough which will have a significant impact on both the industry and healthcare.

This article highlights the concepts of “3D printing”, “additive manufacturing” and “LaserMelting”, and shows how far advanced the technology of 3D-printed dentures already is.

Delimitation of terms in 3D printing

It is essential to understand the differences between “3D printing”, “additive manufacturing” and “LaserMelting”. “Additive manufacturing” is the broad technical term for the term “3D printing,” which is used more colloquially. This is comparable to the colloquial term “plastic”, which is generally referred to as “polymer” in specialist circles.

And how does the term “LaserMelting” fit into the general picture? LaserMelting or selective laser melting (SLM) is an additive manufacturing process and at the same time a 3D printing process in which powdered materials are selectively melted layer by layer by laser beam and thus bonded to the underlying layer.

It is a common misconception that LaserMelting is only used for metal 3D printing. While metal alloys are primarily processed, other material groups such as ceramics can also be processed using this technique. However, LaserMelting of ceramics is very energy intensive and both precision and surface finish are not optimal. For ceramic materials and the additive manufacturing of ceramic precision components, the LCM process is more suitable.

Misunderstandings in laboratory situations

In the laboratory, 3D printing is often understood to refer exclusively to polymer 3D printing. However, this is a misunderstanding, as LaserMelting is also a 3D printing process. Polymer was the most common additively processed material many years ago. Only later did other materials such as metals and ceramics come along, which are much more difficult to 3D print compared to polymers.

This historical development has led to an outdated terminology, similar to the dental industry, where “CoCr” is always referred to as “non-precious metal”, although titanium, for example, also counts as a non-precious metal.

Historical hurdles for 3D printed dentures

To date, polymer 3D printing in dentistry has been predominantly limited to the production of assistive devices, as the materials are not approved to remain in patients’ oral cavities permanently. This is because the polymers available for 3D printing do not have the biocompatible properties necessary to remain in the human body. This lack of suitable materials is a significant limitation to the potential applications of polymer 3D printing in dentistry and hinders the development of durable, patient-specific solutions.

There has been significant progress in this area in recent months, and oral-stable materials have already been developed and are currently awaiting approval. Once these materials receive the necessary approvals, it will be possible to produce 3D-printed dental restorations which can remain permanently in the patient’s oral cavity.

Outlook for 3D-printed dentures

On this basis, our partner company CADdent is currently working on various projects in the field of 3D printing, including the printing of splints for bruxists. Despite some challenges yet to be solved, the outlook for the future of 3D printed dentures is very promising.

With advancing technology and improved materials, we will be able to offer high-quality, customized solutions for patients.

Conclusion

3D printing of dental restorations is an innovative and valuable technology which has the potential to revolutionize dentistry. By gaining a deeper understanding of the terms and technologies used, we can realize the full potential of this technology and improve healthcare in the long term.

MINDFAB is proud to be part of this groundbreaking development and will continue to work on developing innovative solutions in the field of 3D printing of dental prostheses.